Retailers typically choose shelf edge strips in common heights such as 32 mm, 39 mm, 40 mm, 45 mm, and 76 mm. Many edge strips are 1000 mm long, or 1-1/4 inches in height. IDmate Manufacturers offer standard and custom sizes to fit different shelving units. The material and intended use of the shelving will influence which size is most suitable.

Choosing the right shelf edge strips can improve product visibility and ensure secure label placement.

Key Takeaways

- Choose the appropriate shelf edge strip height. Some common sizes include 32 mm, 39 mm, 40 mm, 45 mm, and 76 mm. Measure your shelf edges before purchasing. Accurate measurements help the edge strips fit better and save time. Choose the right material if you want durable edge strips. PVC is widely used, but PETG and polycarbonate are stronger and more transparent. Consider convenient adhesive methods. Self-adhesive edge strips are easy to use and require no tools. You can obtain custom sizes and features. Stores can request special designs to match their branding and layout.

Shelf Edge Strips Standard Sizes

Common Heights and Lengths

Retailers use shelf edge strips to help organize merchandise. These strips display prices and keep shelves tidy. They come in various sizes to fit most shelves. The most common heights are 32mm, 39mm, 40mm, 45mm, and 76mm. Stores also use 1-1/4 inch high strips for holding labels. Standard lengths are typically 1000mm. Some strips are as short as 50mm and as long as 2520mm. This helps them fit shelves of different widths.

Tip: Choosing the right size ensures labels are clearly visible and helps them stay in place. This makes shopping more convenient for customers.

The table below lists common insertion heights and lengths found in stores:

| Attribute | Details |

|---|---|

| Insert Heights | 15 mm – 73 mm |

| Lengths | 50 mm – 2,520 mm |

| Material | PVC |

| Usage | Convenience stores, supermarkets, retail |

Typical Thicknesses

Thickness is crucial for the strength of shelf edge banding. Most edge banding is 0.4 mm thick, suitable for lightweight display shelves. Some edge banding is 3 mm or thicker, suitable for heavy-duty applications. For general shelving, a thickness of 3/4 inch (19 mm) works well. It’s strong enough and not too expensive. Edge banding 1 inch (25 mm) or thicker provides better support for heavier loads.

The table below shows common thicknesses and applications:

| Thickness Range | Material Type | Application Impact |

|---|---|---|

| 0.4 mm | PVC, ABS | For light use |

| 3 mm or thicker | Impact-resistant | For tough jobs |

| 5 mm | Solid wood | For strong, fancy shelves |

Adhesive Options

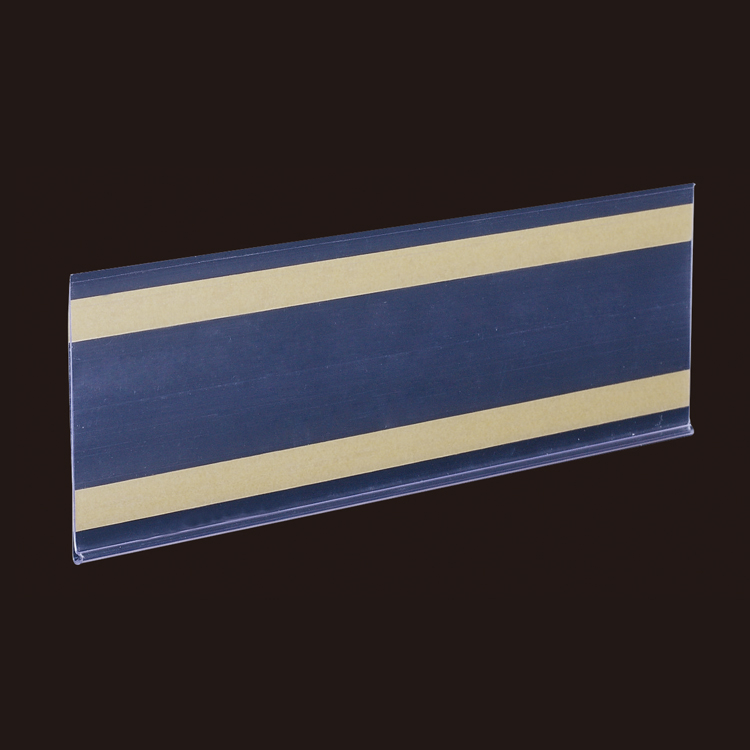

Shelf edging strips are available with different adhesives for easy installation. Pre-coated hot-melt adhesive edging strips are quick to use. They are available in a 3/4-inch width to fully cover the edge, and also in a 1/2-inch width for thinner edges. Self-adhesive edging strips are easy to install and require no tools. The tape is typically 0.6 mm thick. Thicker tapes offer better adhesion and are suitable for heavy-duty applications.

| Adhesive Type | Size Considerations |

|---|---|

| Pre-glued hot melt adhesive | Easy to use; 3/4 inch width for full coverage, 1/2 inch for thin edges |

| Self-adhesive options | Easy to install; size affects fit |

| Thickness | Most tapes are 0.6 mm thick; thicker tapes are best for heavy-duty applications |

Materials for Shelf Edge Strips

Manufacturers use different materials to make shelf edge strips. Each material has its advantages. PVC is the most common material because it is easy to bend and inexpensive. PETG and polycarbonate are stronger and more transparent. They perform well in busy stores. ASA is resistant to sunlight and chemical corrosion. It is suitable for harsh store environments.

Retailers should consider the type of shelving and the expected wear and tear. Choosing the right material and size helps extend the lifespan of the edge strips. It also keeps the shelves looking neat and professional.

Choosing the Right Size

Shelf Type and Compatibility

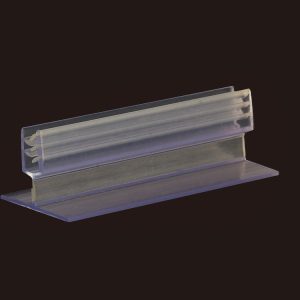

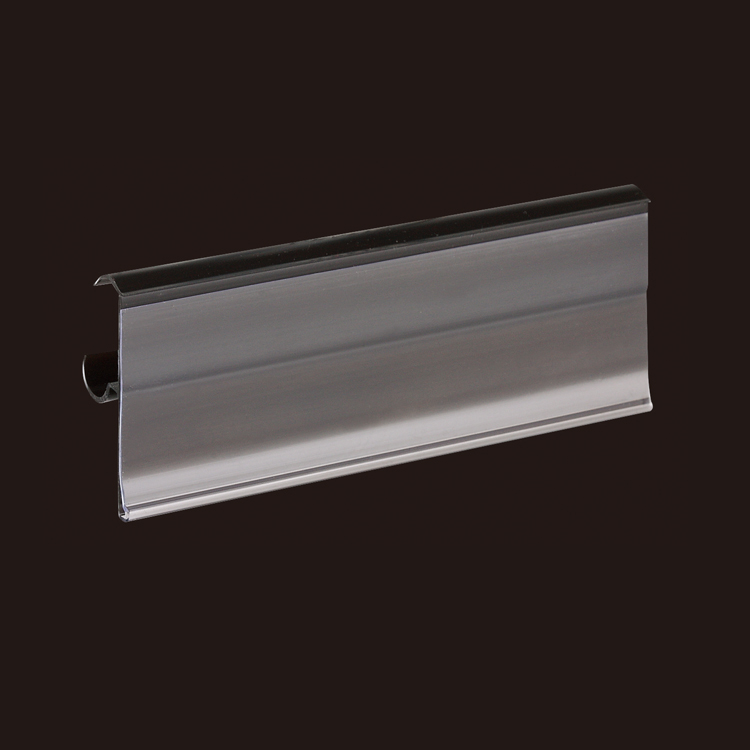

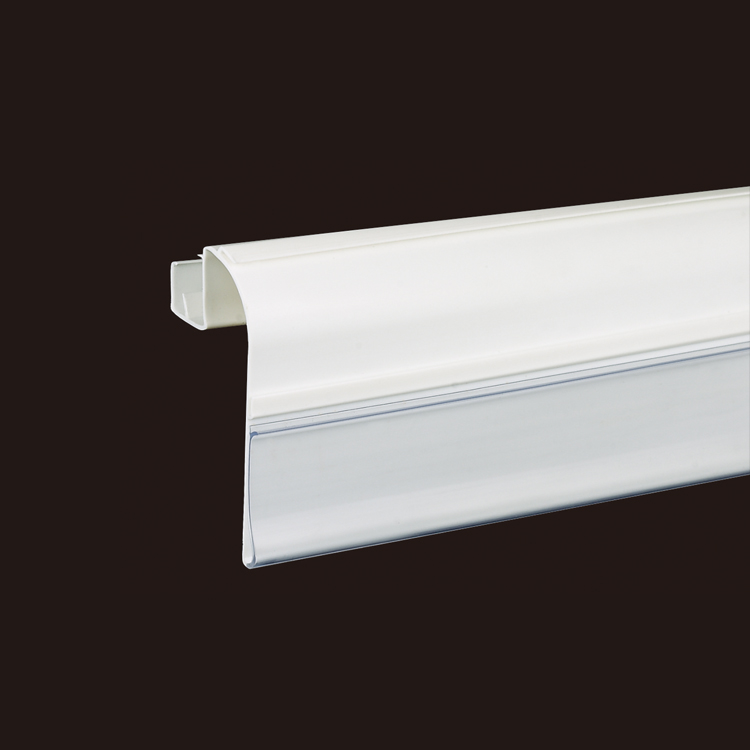

First, you need to understand your shelf type. Shelves used in stores are made of materials including metal, wood, glass, or cardboard. Each shelf requires a suitable edge strip. Adhesive edge strips are best suited for smooth metal or glass surfaces. Clip-on edge strips are more suitable for wooden or cardboard shelves. Some shelves require specific colors or shapes to match the store’s style.

Additional features can help shelves function better. Hinges, dust covers, and curved shapes add more functionality. Double-angle edge strips allow labels to be read from multiple angles. POS inserts allow for easy replacement of promotional signage. Be sure to check the thickness and shape of the shelf edge. This can prevent problems such as mismatched sizes or damage.

Tip: Measure the shelf edge before purchasing. Use a tape measure to measure the height and width. Write down the dimensions so you don’t forget them.

| Issue | Description |

|---|---|

| Size and Thickness | If the shelf is too thick or too thin, the edge strip may not fit properly. |

| Risk of Damage | Forcing the edge strip into place may damage the bracket or fasteners. |

Store display personnel must understand the styles and brands of shelving units. This helps ensure proper installation of edge strips and extends their lifespan.

- Shelf type is important: metal, wood, glass, or cardboard.

- Installation method: Adhesive for secure fixing, clip-on for ease of use.

- Customization: Color, size, and additional features.

- Choose edge strips that match the shelving for optimal result

Display and Label Needs

The way products and labels are displayed is also important. Stores use label strips to hold price tags, barcodes, or promotional signs. This shelf edge label holder is suitable for 1-1/4 inch price tag slots. This size label is clear and easy to read. Self-adhesive data strips securely hold paper labels. The height and length of the label strip should match the label size for a neat and aesthetically pleasing appearance.

Different stores require different label strips. Grocery stores frequently change prices, so they need flexible label strips. Electronics stores use larger label strips to display information on digital screens. Fashion stores need aesthetically pleasing label strips to display promotional information. Home improvement stores use standard-sized label strips to clearly display prices.

| Retail Sector | Display Needs | Impact on Strip Size Selection |

|---|---|---|

| Grocery | Prices change frequently, requiring clear labels. | Requires flexible and adjustable label strip sizes. |

| Electronics | Rapid product updates, requiring digital displays. | UUses larger label strips to display constantly changing information. |

| Fashion | Promotional signage, emphasizing aesthetics. | Different sizes are chosen based on different display needs. |

| Home Improvement | Prices are relatively stable, but contain a large amount of information. | Uses standard sizes for easy reading. |

Stores should choose appropriate label strip sizes based on labeling and display needs. This keeps shelves organized and helps customers quickly find the information they need.

Custom Shelf Edge Strips

Custom Sizes and Shapes

Retailers often require shelf edge strips that fit unique shelving or branding needs. IDmate offers custom sizes and shapes to match any store layout. They can adjust the depth, width, and style to accommodate metal, wood, or glass shelving. Custom designs range from simple clear strips to eye-catching, brightly colored holders. This flexibility helps stores create a look that aligns with their brand image and makes shopping more convenient for customers.

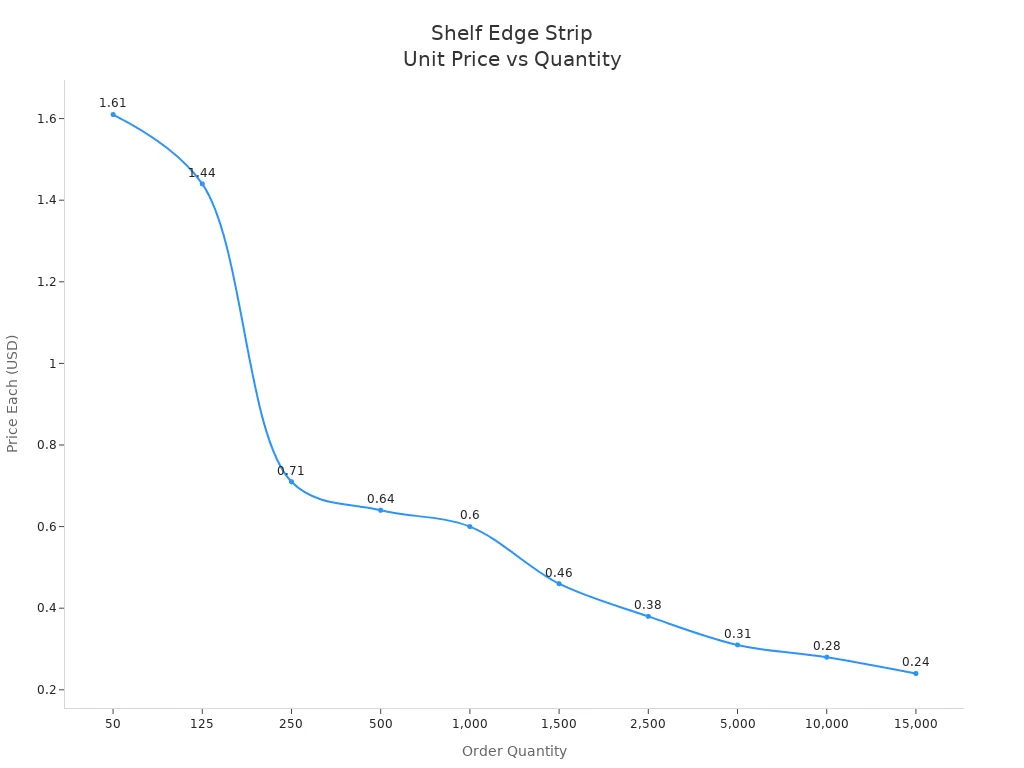

IDmate supports both small and large orders. The company’s flexible minimum order quantity (MOQ) makes it easy for businesses to order as few as 50 pieces. The price per strip decreases as the order quantity increases. The table below shows how the price changes with quantity:

Stores can add features such as double-sided adhesive or custom printing. Special edition orders must be placed in increments of 50 units, and a small setup fee applies to each version. The IDmate team provides design, sample production, and fast delivery services. Most samples ship within 3-5 days, and bulk orders typically ship within 7-15 days.

Note: Custom printing orders may have a 10% quantity variance. Production time depends on order quantity and design.

How to Measure for Custom Orders

Accurate measurements ensure that custom shelf edge strips fit perfectly. Stores should use a tape measure to measure the height, width, and depth of the shelves. A spirit level helps to keep the edge strips straight. For wooden shelves, sanding and applying a finish may be necessary before installation. For some shelves that are more difficult to install, brackets or mounting accessories can be used to assist with installation.

Measurement Steps:

- Measure the height and width of the shelf edge using a tape measure.

- Check the thickness of the shelf.

- Record all measurements.

- Use a spirit level to ensure the edge banding is installed straight.

- Provide this information to the manufacturer.

The IDmate team reviews every order and provides a confirmation draft via email within two business days. They employ a rigorous quality control process and hold ISO 9001 certification. Customers trust IDmate for timely delivery and reliable products.

Tip: Always double-check your measurements before placing an order. This saves time and avoids errors.

Shelf Edge Strip Size Table

Choosing the right shelf edge strip size helps retailers keep shelves neat and organized, with labels clearly visible. Many buyers want to quickly compare products of different sizes. The table below clearly summarizes the most common shelf edge strip sizes, including standard heights, lengths, and thicknesses commonly used in stores worldwide.

| Height (mm) | Height (inch) | Length (mm) | Length (inch) | Thickness (mm) | Typical Material |

|---|---|---|---|---|---|

| 15 | 0.59 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 32 | 1.26 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 39 | 1.54 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 40 | 1.57 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 45 | 1.77 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 76 | 2.99 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

| 1-1/4″ | 1.25 | 50–2,520 | 2–99 | 0.4–3.0 | PVC, PETG |

Tip: Be sure to measure your shelf edge dimensions before ordering. This ensures a perfect fit and avoids wasted time.

Buyers should consider several important factors when choosing shelf edge strips:

- Customer expectations influence the choice of edge strip size and brand. Retailers typically prefer specific configurations that match their store’s style.

- Packaging is also important. Buyers need to check the thickness, weight, and type of hanging holes of the edge strips. These details affect the display and ease of installation.

- Retail operations also influence the decision. Some stores require pre-assembled edge strips for quick installation, while others need edge strips that are easy to install manually.

A quick reference table can help buyers compare various options at a glance, saving time and simplifying the selection process. Retailers who choose the right size and packaging can enhance shelf appearance and boost sales. Custom sizes are always available for special needs.

Choosing the right shelf edge strip size helps stores maintain neat shelves and clearly visible labels. Common sizes such as 32mm, 39mm, 40mm, 45mm, and 76mm meet most needs. Always measure your shelf edge dimensions before placing an order. If standard sizes are not suitable, stores can request custom solutions. IDmate provides expert advice and fast service for any display project.

FAQ

What are the most common shelf edge strip sizes?

Retailers typically choose a height of 39 mm or 1-1/4 inches. These sizes work with most shelving and label types. They help stores clearly display prices and keep shelves neat and organized.

Can shelf edge strips be cut to fit any shelf?

Yes! Many edge strips come in longer lengths. Staff can cut them with scissors or a utility knife. This makes installation quick and easy.

Which material is the most durable for shelf edge strips?

Polycarbonate and PETG materials are the most durable for edge strips. These materials are wear-resistant and less prone to cracking. They are ideal for high-traffic, frequently used stores.

How quickly can IDmate deliver custom shelf edge strips?

Most IDmate samples ship within 3-5 days. Bulk orders typically ship within 7-15 days. Fast delivery helps stores quickly update their shelf displays.

Do shelf edge strips support custom printing?

Yes, IDmate offers custom printing services. Stores can add logos, colors, or special information. Custom edge strips can enhance brand visibility and attract customers.