Acrylic-based permanent adhesives are the best choice for most labels. Many stores use this adhesive because of its long-lasting adhesion. It is suitable for shelves, sign holders, and display hooks. The choice of the best adhesive depends on the surface material of the label and the application location. People consider factors such as the label’s material, toughness, and the application temperature before choosing a permanent adhesive. A clean surface helps the adhesive bond better. A rough or dirty surface will affect the label’s durability. Permanent adhesives are suitable for displays where labels need to be worn for a long time.

- The label’s material, surface feel, and expected lifespan are all factors in choosing the best adhesive.

- The application location and application environment of the label are also crucial when choosing a permanent adhesive.

Key Takeaways

- Acrylic-based permanent adhesives are suitable for most labels. They are strong and not easily affected by weather. – Before choosing an adhesive, consider the surface material of the label and the application location. Smooth surfaces require one type of adhesive, while rough or porous surfaces require another. – Test the adhesive’s strength through peel and shear tests. This helps ensure that the label adheres firmly under suitable conditions. – Removable adhesives are ideal for labels that are only used for a short period. You can easily remove them without leaving sticky residue. Understanding your label’s needs helps you choose the best adhesive. This results in better label performance and a longer lifespan.

Types of Label Adhesive

Choosing the right label adhesive is crucial in a store. IDmate has extensive experience in label holders and POS accessories. They understand the importance of selecting the right adhesive for the specific application. A wide variety of label adhesives are used in stores and packaging.

Rubber-Based Adhesives

Rubber-based adhesives bond quickly and are suitable for a variety of surfaces. They are popular for applying labels that require strong adhesion. These adhesives are water-resistant and bond to plastics, metals, and rubber. Some adhesives, such as natural rubber, can be used at temperatures up to 60°C. Others, such as neoprene, are oil and solvent resistant. The following is a table of commonly used rubber-based adhesives:

| Type of Adhesive | Key Characteristics | Applications |

|---|---|---|

| Natural Rubber | Good water resistance, good bonding flexibility, maximum operating temperature up to 60°C | Plastics, Rubber, General Purpose Labels |

| Neoprene Rubber | Water-resistant, oil-resistant, solvent-resistant; strong adhesion | Metal, Wood, Plastic, Industrial Labels |

| Acrylonitrile Butadiene (Nitrile) | High shear strength, used for bonding rubber to metals | Rubber, PVC, Metal Labels |

| Butyl Rubber | Water-resistant, easy to apply | Automotive, Construction, Tape Labels |

| Styrene Butadiene Rubber | Pressure-sensitive adhesive, used for tapes and labels | Metal Trim, Felt Carpets, Label Adhesives |

Acrylic-Based Adhesives

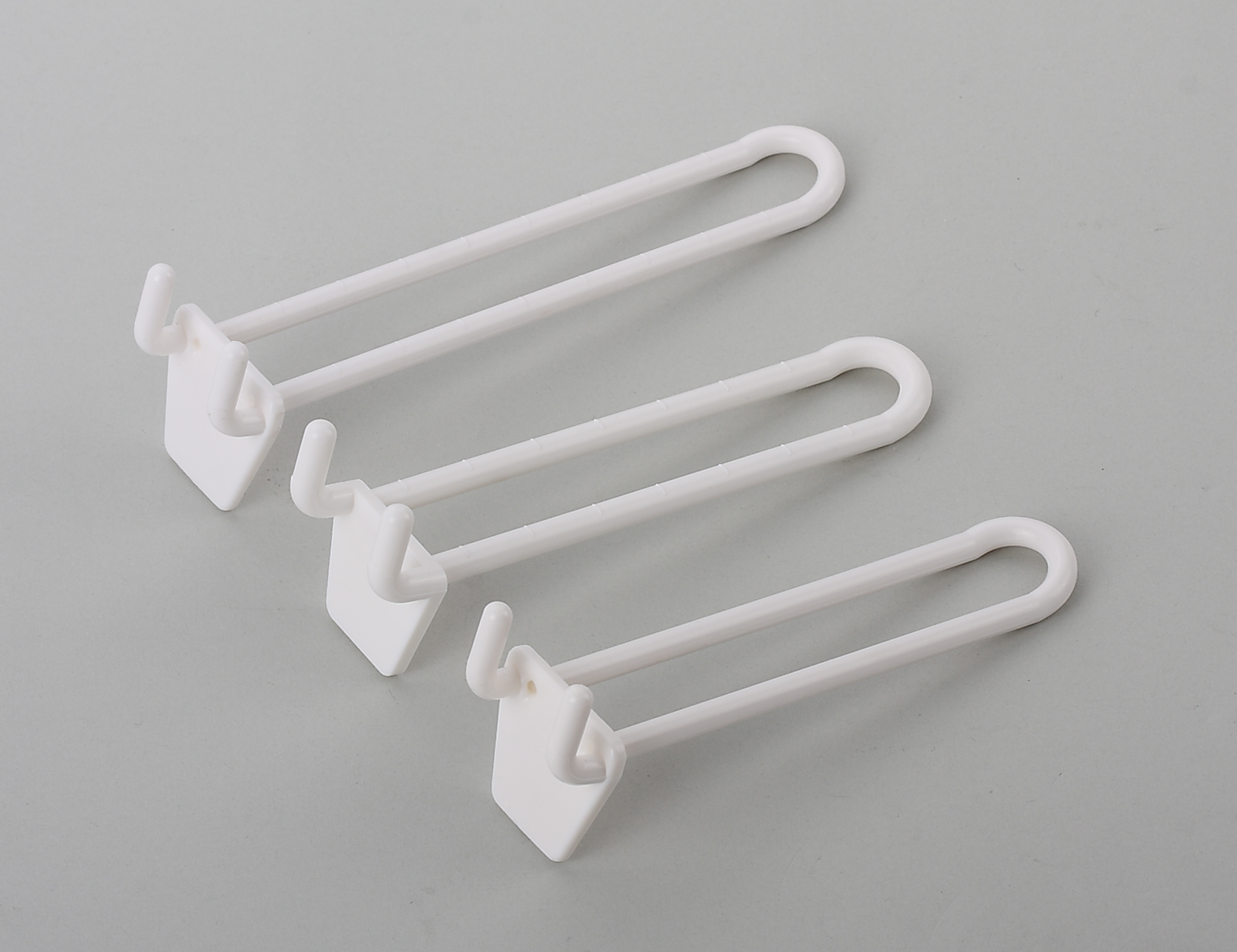

Acrylic adhesives are durable and weather-resistant. Many shops use acrylic label adhesives because they are suitable for a variety of harsh environments. These adhesives firmly bond labels even in direct sunlight, high temperatures, or extreme cold without yellowing or decomposing. Acrylic adhesives are suitable for plastics, metals, and glass. They are ideal for retail shelves, sign holders, and display hooks.

Tip:Acrylic label adhesives are ideal for outdoor displays and are suitable for locations with significant temperature variations. They keep labels looking good and firmly attached.

- Acrylic adhesives are UV resistant and oxidation resistant.

- They are suitable for both indoor and outdoor environments.

- They allow labels to adhere firmly for many years.

Specialty and Blended Adhesives

Some label adhesives are designed for special purposes. Specialty adhesives can withstand chemicals, extreme heat, or extreme cold. Hybrid adhesives combine multiple materials to achieve optimal performance. The following is a table of commonly used specialty adhesives:

| Adhesive Type | Characteristics | Applications |

|---|---|---|

| Chemical Resistant | Maintains strong adhesion even in corrosive environments | Laboratory, Medical, Industrial Labels |

| High temperature | Works up to 500°F (260°C) | Automotive, Electronics, Manufacturing |

| Low temperature | Binders can bond even in freezing conditions down to -20°F | Freezer, Refrigerated Labels |

Some blended adhesives incorporate epoxy or polyurethane for enhanced strength. Acrylic blended adhesives are oil and acid resistant and suitable for factories and auto repair shops. These specialty label adhesives help labels adhere firmly to surfaces where ordinary adhesives cannot.

Adhesive Performance

The performance of label adhesives is crucial in stores and factories. People want labels to adhere firmly or peel off easily. Some labels only require a light press to stick. Let’s look at how different adhesives work and their best application scenarios.

Permanent Adhesives

Permanent adhesives make labels last a long time. They maintain the integrity of the label during transportation and daily use. Stores commonly use permanent adhesives to create product labels. These adhesives are suitable for products such as wine bottles, cleaning agents, and outdoor gear. Labels using permanent adhesives are waterproof, chemically resistant, and sun-resistant.

Here are some application scenarios for permanent adhesives:

- Logistics: Labels won’t fall off during transportation.

- Retail: Product labels are aesthetically pleasing and won’t easily fall off.

- Manufacturing: Labels adhere firmly to machines and tools.

- Inventory Management: Labels help track items and comply with regulations.

- Wine Bottles: Labels won’t fall off when wet or touched.

- Household Cleaning Agents: Labels won’t be damaged by liquid spills.

- Outdoor Gear: Labels remain secure in harsh weather conditions.

Permanent adhesives are difficult to remove and may damage labels or surfaces. These adhesives are typically chosen when durable labels are required.

Tip: Test label adhesives before using them on a large number of items. Perform peel, shear, and tensile tests to check their strength and durability.

| Metric | Description |

|---|---|

| Ultimate Adhesion | Indicates the adhesive strength after drying. |

| Shear Force | Indicates the force required for the label to move laterally. |

| Mandrel Hold | Checks if the adhesive can bend and stick to bumpy surfaces. |

| Operating Temperature | Indicates the effect of temperature on adhesive performance. |

Removable Adhesives

Removable adhesives allow labels to be easily removed without leaving sticky residue. They are commonly used for price tags and promotional stickers. These adhesives make labels easy to peel off. Removable adhesives are suitable for short-term use.

- Removable adhesives do not leave sticky residue.

- This adhesive is suitable for labels that do not require durability.

- It is used to make price tags and discount labels.

- Removable adhesives are ideal for reusable containers.

Permanent adhesives are not suitable for temporary labels. They are too sticky and difficult to remove.

Pressure-Sensitive Adhesives

Pressure-sensitive adhesives bond simply by pressing. No heating, water, or chemicals are required. People like pressure-sensitive adhesives because they are easy to use. Adhesion strength depends on the pressure applied and the surface being applied. Temperature and humidity affect adhesion.

- Pressure-sensitive adhesives are suitable for a variety of surfaces.

- They are quick and easy to use.

- Proper pressing helps labels adhere better.

- These adhesives are widely used in shops, packaging, and offices.

Testing label adhesives helps people choose the right one. Peel and shear tests can show adhesion strength. Tests can also check the adhesive’s heat and water resistance. ASTM D3330 and ASTM D6252 are common methods for testing pressure-sensitive label adhesives.

Adhesive Surface Compatibility

When choosing a label adhesive, the surface should be considered first. Some surfaces help labels adhere firmly, while others require special adhesives for a secure bond. Store displays and shelves utilize a variety of surfaces, each affecting label adhesion.

Smooth Surfaces

Smooth surfaces include glass, metal, or glossy plastic. Labels look clean and neat on these surfaces. High surface energy helps adhesives bond better. Most adhesives work well on smooth surfaces. If the surface energy is low, labels may sometimes fall off. Some plastics have low surface energy. Specially formulated acrylic adhesives help labels adhere firmly.

The table below shows how surface energy affects adhesive strength:

| Surface Type | Surface Energy (dynes/cm) | Adhesive Compatibility |

|---|---|---|

| High Surface Energy | >40 | All adhesives bond well |

| Medium Surface Energy | 35-40 | Most adhesives bond well |

| Low Surface Energy | <35 | Special low surface energy adhesives are required |

Tip: Clean smooth surfaces before applying labels. Dust or oil can reduce adhesive strength.

Textured and Porous Surfaces

Textured and porous surfaces include materials like cardboard, wood, or fabric. These surfaces have tiny bumps or pores. Adhesives may not cover every spot, resulting in poor label adhesion. Rubber-based or high-tack adhesives work better on these surfaces. They adhere better to rough surfaces, thus securing the label firmly.

- Adhesives to porous surfaces require stronger adhesives to maintain a firm hold.

- High-tack adhesives help labels adhere to rough surfaces.

- Stores typically use these types of adhesives to make shelf labels and price tags.

Challenging Materials

Some materials are difficult to label. For example, plastics like polyurethane or silicone are resistant to most adhesives. Metals and plastics deform under alternating temperatures, which can cause labels to detach. Fabrics absorb adhesive, leading to label detachment. Water, sunlight, and chemicals also reduce adhesive tack over time.

- Adhesives must be able to adapt to different surface chemistry.

- Low surface energy plastics require special adhesive formulations.

- High temperatures can deform metals and plastics, causing labels to detach.

- Water and sunlight can break down adhesives, causing labels to peel off.

Stores test adhesives on hard surfaces before using them. Choosing the right adhesive helps ensure labels look good and last.

Adhesive Environmental Factors

Temperature and Humidity

Temperature and humidity affect label adhesion. Labels adhere best when the air is not too hot or too humid. Some adhesives soften if the temperature is too high. Softened adhesive can cause label edges to stick together. Sticky edges can jam the printer. In very humid air, labels may fall off. Sometimes, labels stick together, resulting in waste. Some adhesives perform better at higher temperatures. Silicone-based adhesives remain strong even at high temperatures. These adhesives are suitable for labels on electronics or machinery. People should check the air and temperature before choosing an adhesive.

- Labels adhere best at suitable temperature and humidity.

- High temperature and humidity can soften and thicken adhesives.

- Silicone adhesives are suitable for labels in high-temperature environments.

Outdoor and Indoor Use

Labels have different requirements for indoor and outdoor use. Outdoor labels must be able to withstand rain, sunlight, and weather changes. Indoor labels are placed in environments with stable air and temperature, so they require minimal protection. Adhesive formulations vary depending on the label’s intended use.

The table below lists the differences between indoor and outdoor adhesives:

| Property | Outdoor Adhesives | Indoor Adhesives |

|---|---|---|

| Flexibility | Excellent flexibility, adaptable to temperature changes | Limited flexibility |

| Water Resistance | Excellent water resistance | Poor water resistance |

| UV Resistance | Contains UV stabilizers | Lacks UV resistance |

Environmentally conscious consumers want labels that are more environmentally friendly. Compostable labels are biodegradable and require special adhesives. Recyclable labels use water-based adhesives for easy recycling. Washable adhesives make the labels easy to remove during recycling.

- Compostable labels require safe adhesives to ensure compostability.

- Recyclable labels use water-based adhesives for easy recycling.

- Washable adhesives help labels peel off easily for recycling.

Adhesive Comparison Chart

Choosing the right label adhesive can be difficult. Each adhesive has its optimal application. Shop, warehouse, and office workers are looking for adhesives that meet their needs. The following chart compares the performance of commonly used label adhesives:

| Adhesive Type | Description | Performance Factors | Typical Applications |

|---|---|---|---|

| Permanent | Strong adhesion, difficult to remove | High adhesion, low removability | Transportation, product branding, packaging |

| Removable | Easy to peel off, leaves no residue | Medium adhesion, high removability | Price tags, promotional stickers, temporary labels |

| Repositionable | Removable and reusable multiple times | Low adhesion, high initial tack | Temporary signage, hand-applied labels |

| Acrylic-Based | UV resistant, weather resistant, chemical resistant | High adhesion, good bonding, low shear force | Outdoor labels, metal, plastic, wood surfaces |

| Rubber-Based | Fast bonding, adhesive Adhesive to uneven surfaces | High tack, medium adhesion, variable shear strength | Indoor transport, cardboard, wood, plastic |

| Durable | Suitable for rough surfaces and harsh environments | Resistant to chemical corrosion, water, and weathering | Suitable for industrial, outdoor, and rough surfaces |

| All-Temperature | Maintains tackiness at both high and low temperatures | Wide operating temperature range | Suitable for refrigerated foods and beverages |

| Freezer-Grade | Suitable for frozen environments | Maintains tackiness at low temperatures | Suitable for frozen food packaging |

| Heat-Activated | Requires heating to adhere, washable | Abrasion and wash resistant | Suitable for clothing labels and textiles |

| Water-Soluble | Easy to clean, environmentally friendly | Soluble in water | Recyclable containers |

Tip: Users should check the surface to be applied and the label location. Some adhesives work better in cold or humid environments. Others maintain tackiness more under sunlight or on rough surfaces.

Key Performance Factors:

- Adhesion: The label adheres firmly with just a gentle push.

- Adhesion Strength: The label adheres firmly and is not easily detached.

- Shear Strength: The adhesive remains firm even when pulled from the side.

Environmental factors are also important for labels. Outdoor labels require adhesives that can withstand rain and sun. Freeze-grade adhesives ensure labels adhere firmly in low-temperature environments. Water-based adhesives are easier to recycle and more environmentally friendly.

Shops and factories often use permanent adhesives for labels intended for long-term use. Removable adhesives are best suited for short-term use. Repositionable adhesives allow you to move labels without losing their stickiness. Choosing the right adhesive helps ensure labels look good and function well.

Choosing the Best Adhesive

Choosing the right label adhesive may seem difficult. But it becomes easy by following these steps. This method is used in shops, warehouses, and hospitals. The right adhesive ensures labels adhere firmly, look good, and are secure.

Selection Steps

Experts recommend using a simple approach to choosing an adhesive. Here is their workflow:

- Understanding the Surface

First, determine what material the label will be on. Is it glass, plastic, metal, or cardboard? Each material requires a special adhesive to ensure a strong bond. - Consider Environmental Factors

Next, consider where the label will be applied. Will it be exposed to high temperatures, low temperatures, water, or sunlight? These factors all affect the adhesive’s bonding strength. - Choose Label Materials That Meet Your Needs

Choose label materials that meet your needs. Some labels must be able to remain outdoors for extended periods. Others only need to maintain their appearance for a short time. - Check Adhesion Strength

Determine whether you want the labels to be permanently adhered or easily removable. Permanent adhesives are best suited for long-term use. Removable adhesives are suitable for short-term applications. - Consider Design and Customization

Design is crucial. Rounded corner labels stay on longer than square labels. Custom shapes and colors help your brand stand out. - Consider Budget and Cost-Effectiveness

Consider your budget. Buying in bulk can save costs. Premium adhesives are more expensive but waste less and are less prone to damage. - Check Regulatory and Safety Rules

Ensure that the adhesive you use complies with safety regulations, especially in the food or pharmaceutical industries. Adhesives must comply with FDA regulations and be harmless.

Tip: Always test label samples before purchasing in bulk. This helps you determine if the adhesive is suitable for your store or warehouse.

The table below lists some innovative ideas that can benefit stores and brands:

| Innovation | Description | Benefits |

|---|---|---|

| AD CleanGlass™ | Washable labels for reusable glass packaging | Easy to remove, easier to recycle |

| AD CleanFiber™ | Certified paper label solution | Higher recycling rate |

| Infinity Collection | Premium label portfolio | Creative freedom, reliable use |

| NCR Sticky Media | Thermal receipt paper with adhesive | Faster labeling, less waste |

Common Mistakes

People sometimes make mistakes when choosing adhesives. These mistakes can waste time, cause product damage, or create safety issues. Here are some of the most common problems:

- Choosing a label that doesn’t fit the container surface. If the adhesive on the label doesn’t fit the container, the label may fall off.

- Ignoring environmental factors. High temperatures, low temperatures, or humidity can weaken the adhesive, causing the label to fall off.

- Using the wrong adhesive in the healthcare field. Labels may detach from syringes or vials, endangering patient safety.

- Chemical exposure is not considered. Disinfectants can damage labels, rendering them illegible.

- Design details are ignored. Square labels are more prone to detachment than round ones. Rounded corner labels last three times longer than square ones.

- Failure to understand failure mechanisms. This leads to unreliable suppliers and increases post-shipment claims.

- Regulatory compliance is forgotten. Food or drug labels must use adhesives that meet safety standards.

Note: In stores, choosing inferior adhesives can cause printer jams, increasing workload. Customers may be dissatisfied. Using better labels and ribbons can reduce downtime by 35% and lower costs by 25%.

Below is a table containing real-world case studies:

| Case Study | Problems Faced | Solutions | Results |

|---|---|---|---|

| Retail Logistics Company | Printer downtime, poor print quality | High-quality labels and ribbons | 35% reduction in downtime, 25% reduction in costs |

| Healthcare Provider | Label aging, compliance issues | Medical-grade labels | More durable, safer for patients |

| Warehouse & Distribution | Incorrect shipping labels, customer complaints | High-quality labels and ribbons | Accurate shipping, greater customer satisfaction |

Stores and brands can avoid these mistakes by listening to expert advice. Understanding adhesive types, conducting real-world testing, and adhering to safety regulations helps improve label effectiveness and lifespan.

Tip: Balance cost, performance, and needs for optimal results. Choose the adhesive best suited to your needs for maximum value.

Choosing the right label adhesive helps businesses keep their labels neat and secure. If the chosen adhesive matches the label surface and the placement area, the labels will adhere firmly and look good. Acrylic-based permanent adhesives offer long-lasting adhesion and extremely high strength, maintaining a clear bond even in harsh environments. These adhesives are suitable for a variety of surfaces. Many businesses want to know which adhesive works best and how temperature changes affect its tack. For professional assistance, they consult specialized suppliers like IDmate.

FAQ

What is the best adhesive for store shelf labels?

Acrylic-based permanent adhesives are the best choice for shelf labels. They adhere firmly to plastic, metal, and glass. Stores typically use them for price tags and product information labels.

Will a sticky residue be left after removing the label?

Removable adhesives allow you to easily remove labels without leaving sticky residue. They are commonly used for price tags and promotional stickers.

How does temperature affect the tackiness of label adhesives?

High temperatures can soften some adhesives. Low temperatures can cause labels to peel off. Acrylic adhesives maintain good tackiness at various temperatures.

Which adhesives are safe for use in food packaging?

Food-grade adhesives comply with the regulations of the U.S. Food and Drug Administration (FDA). They will not harm food or humans. Stores typically use them for labeling snacks, beverages, and fresh produce.