Data Labels should be stored properly to maintain product integrity and protect the company’s reputation. Improper label storage can lead to financial losses, inaccurate data, reputational damage, decreased efficiency, missed opportunities, wasted resources, and lower employee satisfaction:

Temperature and humidity should be controlled,data labels should be kept away from sunlight and water, sturdy packaging should be used, and labels should be stored in an organized manner. If labels are stored improperly, important information on custom-printed labels may be lost. This can lead to product recalls, health issues, and customer complaints. Properly storing product labels ensures all information is safe, reduces risks, and makes label storage simple and reliable.

Key Takeaways

- Store data labels in a cool, dry place at a temperature between 65°F and 75°F. This helps maintain the labels in good condition.

- Use sturdy packaging to protect data labels from sunlight and water. This prevents fading and peeling.

- Store labels neatly on shelves or in containers. This ensures the labels are safe and easy to find.

- Regularly check labels for expiration dates and damage. This ensures the labels are used properly.

- Train employees on the correct methods for handling labels. This keeps labels intact and reduces waste.

Data Label Storage Environment

Temperature and Humidity Guidelines

A temperature-stable room ensures data label safety. It helps maintain the adhesive’s tackiness. Experts recommend storing labels in a place where the temperature is between 65°F and 75°F. Humidity should be maintained between 45% and 55%. These values prevent labels from curling or peeling. They also help prevent fading. Different label materials react differently to heat and humidity. Some adhesives will fail if the air is too humid or too dry. Others will harden and crack in cold places. Companies need to understand the storage requirements of each label material before choosing a storage location.

Tip: Store data labels in a cool, dry place. Avoid storing them in rooms with large temperature fluctuations or high humidity.

Light and Moisture Protection

Sunlight can quickly damage data labels. Ultraviolet (UV) rays cause text and images to fade, making labels difficult to read. Water weakens the adhesive, causing labels to peel off. Some labels use special inks or waterproof adhesives, but not all labels have this protection. Each label material requires different care methods. Weather-resistant labels are suitable for harsh environments, while standard labels require extra protection.

- Keep labels away from windows and skylights.

- Do not place labels near vents or in well-ventilated areas.

- Use sturdy packaging materials to block sunlight and moisture.

- In humid environments, choose labels with waterproof adhesives.

- For labels used in sunlight, choose UV-resistant inks.

Avoiding Contaminants

If stored improperly, data labels can become contaminated with dust or chemicals. Dust and dirt can affect print quality and adhesion. Standards such as ANSI Z535 and OSHA require labels to be resistant to chemicals and high temperatures. Good storage practices include keeping labels away from concrete floors. Concrete absorbs moisture and dirt. Shelves, storage bins, and sealed containers can protect labels.

| Compliance Theme | Description |

|---|---|

| ANSI Z535 Format | Uses color coding, layout, and signal words to make labels clear and easy to read. |

| Chemical Resistance | Uses materials resistant to chemicals and high temperatures. |

| Pre-formatted Templates | Used for electrical panels and piping to ensure safety and compliance. |

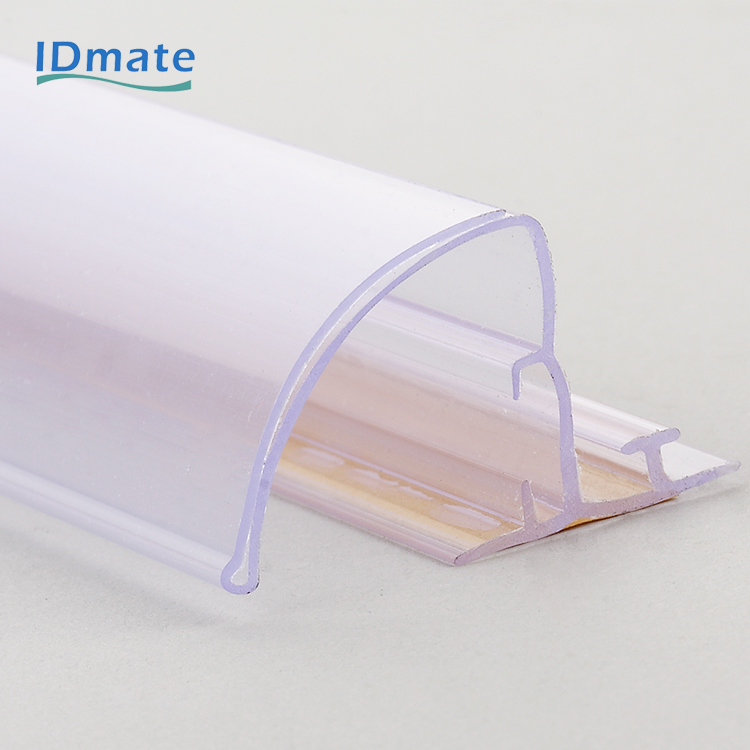

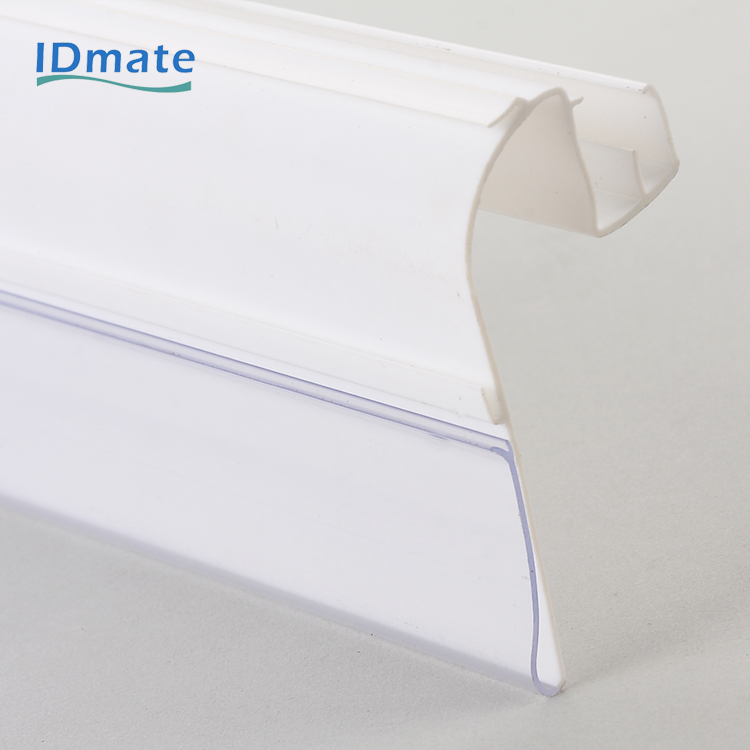

Note: Robust packaging from trusted suppliers like IDmate protects labels from damage during shipping and storage.

How to Store Your Product Data Labels

Choosing Storage Containers

Choosing the right container protects your product data labels. Many companies use original packaging boxes, blister packs, or roll packaging. Original packaging boxes protect against dust and water, but they take up more space and generate more waste. Other containers, such as plastic or metal boxes, are more durable and reusable. The table below compares these options:

| Aspect | Original Packaging (Wraps) | Alternative Containers |

|---|---|---|

| Sterility Process | Starts at step 4, ends at 7, requires disposal | Part of every step, no disposal needed |

| Reprocessing | Not required | Requires special conditions |

| Space Requirement | Less space-efficient | More voluminous, space-consuming |

| Waste | High volume, environmental challenges | Lower waste, potential recycling programs |

| Capital Expenditure | Steady flow for disposables | High initial investment, lower long-term costs |

Plastic, metal, and cardboard each have their advantages. Corrugated cardboard is strong and durable. Plastic containers are waterproof and less prone to breakage. Metal containers provide insulation and protect labels from damage. Businesses should choose the appropriate container based on their needs and label type.

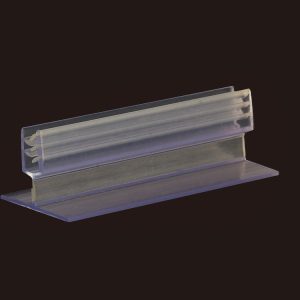

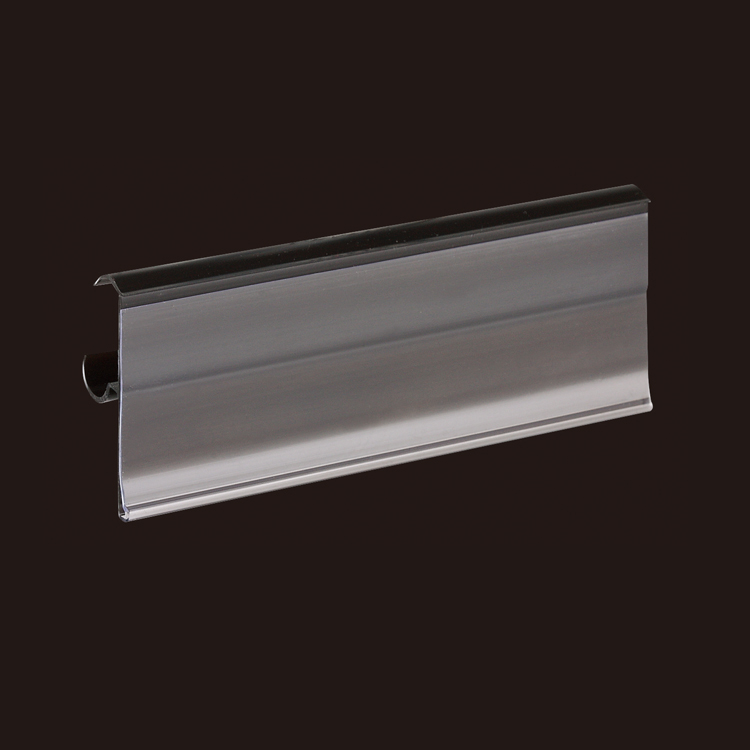

Using Pegboards and Dispensers

Hanging boards and dispensers help keep product data labels neat and organized. Hanging boards allow staff to hang rolls of labels, saving space. This prevents labels from bending or tearing. Data Label dispensers allow you to remove labels without touching the adhesive side. Some storage systems use shelves and dispensers to keep labels organized. These systems also help maintain a stable temperature. This keeps labels in good condition and easy to find.

Tip: Use dispensers and hanging boards to keep labels neat, organized, and readily available. This reduces the number of times labels are handled, keeping them looking good.

Keeping Data Labels Flat and Organized

Storing labels flat prevents them from curling and keeps them looking good. Shelves and storage bins help categorize product labels by type or date. Clear labels on shelves and storage bins make it easy to find the correct labels. Place frequently used labels in easily accessible locations. Safety labels should be easy to see and retrieve. The table below shows methods for keeping labels organized:

| Method | Description |

|---|---|

| Clear labeling | Label shelves and storage bins with easy-to-read fonts. |

| Accessibility | Place items in easily accessible locations, especially for employees with disabilities. |

| Demand placement | Store frequently used labels at the front or at eye level. |

| Safety storage | Store heavy or hazardous items in safe areas on the ground. |

IDmate’s robust packaging and careful inspection ensure labels remain safe during shipping or storage. Their packaging boxes utilize sturdy materials and clever designs to prevent damage. Companies employing these methods can safely store your product labels and keep them in good condition for extended periods.

Best Practices for Storing Data Labels

Handling and Maintenance Tips

Proper handling methods keep labels in good condition. Employees should return labels to their original packaging. This prevents dust from entering and avoids sudden temperature changes. Shelves are better for storing labels than concrete floors. Shelves keep labels dry and safe. Sunlight and high temperatures can fade labels and damage the adhesive. Employees should keep labels away from heat and sunlight. Training helps employees handle labels correctly. Labels should not be bent or mishandled. Each type of label requires different care. Paper labels are best stored in a cool, dry place. Vinyl and polyester labels need to be kept away from high temperatures. Polypropylene labels last longer when stored at temperatures below 75°F. Acrylic adhesives work best in a cool, stable environment. Rubber adhesives require fresh air and stable temperatures.

Tip:Clean storage areas and tools frequently. This prevents dust buildup and keeps labels looking good. Inventory Rotation and Expiration Date Checks

Rotating Stock and Expiry Checks

The company needs to inspect labels regularly. This helps prevent the use of expired or damaged labels. New labels should be inspected upon receipt. Employees should check for label issues at the beginning of each shift. Labels should be inspected again annually, or more frequently in harsh environments. Smart containers equipped with RFID technology can help track labels. The smart containers will alert employees when labels are nearing their expiration date. Mobile tools can assist in managing labels and simplifying the recall process. A FEFO (First Expired, First Out) system prioritizes the use of labels nearing expiration. Employees should always check the expiration date when receiving labels. They should also regularly check inventory. The sales department can assist in handling labels that are nearing expiration.

- Set a minimum shelf life for all labels.

- Closely monitor suppliers who send labels that are nearing expiration.

- Train employees on how to handle expiration dates.

Troubleshooting Common Issues

Label storage presents many challenges. The table below lists common problems and their solutions:

| Issue | Problem Description | Solution |

|---|---|---|

| Misalignment | Labels appear uneven or are the wrong size. | Use alignment tools and check the machine frequently. |

| Adhesion Issues | Labels peel off or do not adhere properly. | Choose the right adhesive, clean the surface, and use the correct temperature and pressure. |

| Label Tearing | Labels tear during use. | Use durable materials and adjust speed and tension. |

| Fading or Smudging | Print fades or becomes blurry. | Use UV-resistant materials and waterproof ink; store labels properly. |

| Static Electricity | Dust adheres to the labels. | Use anti-static tools and clean the machine frequently. |

Harsh weather, high shelves, and sunlight can damage labels. Using boxes or bags provides extra protection. Waterproof markers and color coding help organize labels. Mark all sides of the boxes so workers can quickly find the labels.

Following these best practices ensures product safety, saves costs, and keeps operations running smoothly.

Proper label storage ensures product safety and enhances your company’s image. Experts recommend using opaque boxes. Labels should be kept cool, dry, and clean. Workers need to follow simple rules. They should use large, easy-to-read fonts. Place labels where people can quickly access them. Durable materials and advanced tools extend label lifespan. Regularly check how labels are stored. This prevents problems and ensures everything runs smoothly.

| Strategy | Benefit |

|---|---|

| Simple rules | Reduce clutter |

| Easy-to-read letters | Improve readability |

| Good label spots | Easy access |

| Durable materials | Longer label lifespan |

| New tools | Increase work efficiency |

Using smart label storage methods ensures label security and helps businesses succeed.

FAQ

How long can data labels be stored before they expire?

Most labels have a shelf life of approximately 1 to 2 years. They require proper storage conditions. Companies should regularly check expiration dates. Prioritizing the use of older labels can reduce waste and ensure product safety.

What is the best way to organize different types of data labels?

Categorize labels by type, size, or date. This allows for quick retrieval. Shelves and storage bins help maintain order. Clear labeling helps workers stay organized. Smart systems can save time and reduce errors.

Why should businesses avoid storing data labels on concrete floors?

Concrete floors absorb moisture. Labels may curl or peel off. They may also lose their adhesive properties. Shelves and storage bins protect labels from damage. Robust packaging like IDmate’s keeps labels in pristine condition.

Can sunlight damage printed data labels?

Sunlight can cause ink to fade and adhesive to fail. UV rays can cause labels to fade and may prevent them from sticking properly. Store labels away from windows. Use packaging that blocks sunlight.

Why is IDmate’s packaging a smart choice for storing data labels?

IDmate uses durable materials and clever design. Their packaging protects labels from water and sunlight. It also prevents damage from rough handling. Businesses trust IDmate because they provide excellent delivery service and high-quality label products.