Label adhesives can be permanent, removable, or repositionable. The best type depends on how the tags will be used and where they will be applied. Choosing the right label adhesive is crucial in a busy store. It can help employees complete tasks faster and keep shelves organized. Some adhesives allow employees to move labels without damaging surfaces. This saves time and reduces errors. Other adhesives securely fix labels in place, ensuring important signage isn’t easily altered. Every store needs the right adhesive to keep operations running smoothly.

Key Takeaways

- Choose the right type of adhesive. You can choose between permanent, removable, or repositionable adhesives. Each type suits different needs. Consider how long you want the labels to stay attached.

- Permanent adhesives are for labels that shouldn’t be moved. For example, safety signs. They are very strong, but may leave a sticky residue when removed.

- Removable adhesives allow for easy label changes. They don’t leave sticky residue. Suitable for short-term promotions or displays.

- Repositionable adhesives allow you to move labels multiple times. They won’t damage surfaces. This is useful for stores that frequently need to change merchandise.

- Always test the adhesive on a small area first. This helps you see if the adhesive is strong enough. It also helps you determine if the label can be removed without damage.

Types of Label Adhesives

Choosing the right label adhesive helps labels perform optimally in a store. There are three main types: permanent, removable, and repositionable. Each type is best suited for different uses. Let’s look at how each type works and where it’s best applied.

Permanent Label Adhesive

Permanent label adhesives keep labels attached for a long time. Once applied, the label is securely fixed in place. These adhesives are suitable for labels that shouldn’t be moved, such as price tags or product information labels. Store employees use permanent adhesives for pressure-sensitive labels because they want the labels to stay put.

Permanent adhesives are inexpensive and effective. They can adhere to plastic, metal, and glass. If you try to remove a label with permanent adhesive, it may leave a sticky residue or damage the surface. This is good for labels that need to be used long-term, but not suitable for labels that need to be changed frequently.

Tip: For signs or labels that should not be moved, such as safety warnings or product barcodes, use permanent label adhesive.

Removable Label Adhesive

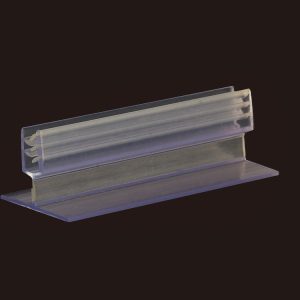

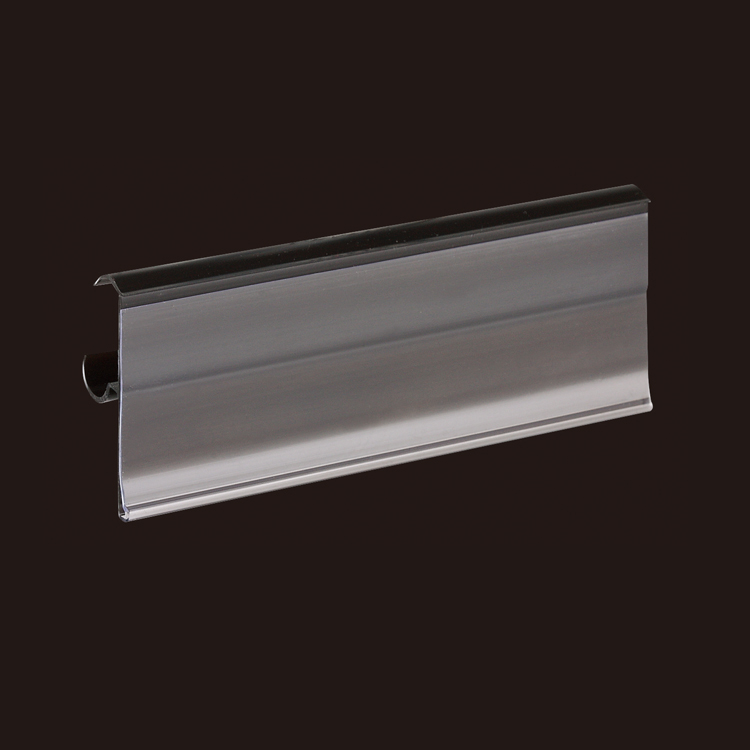

Removable label adhesives have good adhesion but are easy to remove. Workers can easily peel off these labels without leaving sticky residue or damaging the surface. This is very convenient for plastic label holders, data strips, and signs that need frequent changes.

Here are some key advantages of removable adhesives:

| Advantage | Description |

|---|---|

| Residue-free removal | Labels can be peeled off cleanly, keeping shelves tidy. |

| Versatility | They can be applied to plastic, glass, and metal, making them versatile. |

| Environmental friendly | Many products use safe and environmentally friendly materials. |

Stores use removable adhesives for short-term promotions, price changes, or holiday displays. Staff can quickly change labels and keep display areas clean and attractive.

Repositionable Label Adhesive

Repositionable label adhesives offer maximum flexibility. Staff can apply, peel off, and move labels multiple times. This is very useful for busy stores with frequent merchandise changes.

Repositionable adhesives are ideal for plastic sign holders and data strips. Even after moving the labels multiple times, no sticky residue is left behind. This keeps the plastic surface clean and makes it easy to apply new labels. Some repositionable adhesives may become stronger over time, but initially, they allow for easy label repositioning.

Note: Repositionable label adhesives are ideal for stores that frequently need to change prices or product information. Staff can move the labels until everything looks perfect.

Here is a comparison table of the three types of label adhesives:

| Adhesive Type | Best Use | Removal | Surface Compatibility |

|---|---|---|---|

| Permanent adhesive | Long-term, secure label application | Hard | Plastic, metal, glass |

| Removable adhesive | Temporary, changeable labeling | Easy, clean | Plastic, glass, metal |

| Repositionable adhesive | Frequent updates, adjustments | Very easy, clean removal | Plastic, paper, acrylic |

Each type of label adhesive can help stores keep their display areas neat and organized. Stores will choose the best type based on the frequency of label changes, the type of surface used, and whether it’s necessary to avoid sticky residue.

Adhesive Bases for Labels

Choosing the right adhesive substrate helps labels adhere securely and extends their lifespan. Each substrate has its optimal application and surface. There are three main types: acrylic-based, rubber-based, and water-based adhesives.

Acrylic-Based Label Adhesives

Acrylic adhesives are widely used in retail stores. They are durable and suitable for various harsh environments. They adhere well to plastic and acrylic substrates and maintain their tackiness even in humid store environments. Acrylic adhesives do not soften or lose their tackiness when exposed to water. Therefore, they are ideal for labels on refrigerators or supermarket shelves.

Acrylic adhesives can withstand significant temperature changes. They maintain their tackiness in both cold and hot environments, with a temperature range of -40°F to 176°F. Some types, such as RP37 and RP74, are water-resistant, oil-resistant, and UV-resistant. These adhesives are suitable for HDPE, PET, glass, and metal surfaces. Stores use them for clear labels on bottles and for neat signage.

Tip: Use acrylic adhesives in cold or humid areas. They keep labels securely attached even during busy store hours.

Rubber-Based Label Adhesives

Rubber adhesives are strong and provide a secure bond. They are suitable for plastic, metal, and rough surfaces. In busy stores, rubber adhesives help labels stay in place and maintain their tackiness even with frequent handling. Staff use them for price tags and signs that need to be securely attached immediately.

Rubber adhesives form a strong bond, especially on plastic surfaces. They are best suited for indoor use. They are ideal for areas where labels are frequently touched. For metal or difficult-to-adhere surfaces, staff may need to clean or sand the surface first to help the adhesive adhere better.

- Strong adhesion, quick application

- Suitable for busy areas

- Best for indoor use

Water-Based Label Adhesives

Water-based adhesives are safe and easy to use. They are suitable for paper labels and smooth surfaces. Many stores use them for short-term signage and environmentally friendly displays. Water-based adhesives do not have a strong odor and are easy to clean.

These adhesives are best suited for dry indoor environments. They may not be suitable for damp or cold environments. For plastic or acrylic displays, stores typically choose acrylic or rubber adhesives.

| Adhesive Base | Best Surfaces | Key Features | Where to Use |

|---|---|---|---|

| Acrylic | Plastic, acrylic, glass, metal | Handles water, UV, heat, cold | Fridges, outdoors, humid areas |

| Rubber | Plastic, metal, rough surfaces | Fast grip, strong bond, indoor use | Busy aisles, shelf edges |

| Water-based | Paper, cardboard | Safe, easy to remove, eco-friendly | Temporary signs, dry areas |

Each adhesive substrate helps stores keep labels neat and tidy. It ensures labels stay firmly attached. Choosing the right adhesive means labels won’t fall off, and product displays will look professional and attractive.

Factors Affecting Adhesive for Labels

Surface Material and Texture

The type of surface affects how well a label adheres. Smooth surfaces (such as glass and metal) help adhesives bond securely. Labels stay in place on these surfaces. Rough surfaces (such as textured plastic or cardboard) make it difficult for adhesives to adhere because the bonding area is smaller. Stronger adhesives work better on rough surfaces. Stores use permanent adhesives on smooth surfaces for long-lasting signage. Removable adhesives work on a variety of surfaces but may not adhere well to rough surfaces. Repositionable adhesives are for short-term use on smooth or low-surface-energy surfaces. Specialty adhesives help labels adhere to textured plastics.

| Adhesive Type | Compatible Surfaces |

|---|---|

| Permanent Adhesive | Smooth surfaces, such as glass and metal |

| Removable Adhesive | Various surfaces, depending on the adhesive type |

| Repositionable Adhesive | Short-term use on smooth or low-surface-energy surfaces |

| Specialty Adhesives | Textured plastics or low-surface-energy materials |

Tip: Choose an adhesive that matches the surface texture. Permanent adhesives are best for smooth plastics. Specialty adhesives are better for textured plastics.

Environmental and Temperature Considerations

Temperature and humidity affect adhesive performance. Labels adhere more securely in warm environments. Cold or damp surfaces weaken adhesive strength. Stores use permanent adhesive labels in refrigerators or outdoors because they can withstand greater temperature variations. Removable adhesives are best suited for dry indoor environments. Staff should check for frost or condensation before applying labels.

| Application Type | Temperature Range |

|---|---|

| General Adhesives | -65°F to 200°F |

| Freezer Adhesives | Below 32°F |

| Low-Temperature Application | Above 40°F for proper adhesion |

- If possible, apply labels in a warm environment.

- Wait a period of time before moving products to a cold environment.

- Ensure the surface is dry and clean.

Application and Removal Needs

How labels are used and removed helps determine the appropriate adhesive. Removable adhesives are suitable for temporary labels, inventory management, and events. Staff can easily peel off these labels without causing damage or leaving sticky residue. Permanent adhesives are best for labels that need to remain in place for extended periods, such as product information or safety signs. The purpose of the label dictates whether a strong adhesive is needed. Surface texture and porosity are also important. Strong adhesives are suitable for robust materials. Fragile items require easily removable labels.

- Removable adhesive is for temporary uses.

- It comes off without damage or sticky stuff.

- Permanent adhesive is for labels that should stay put.

Note: Choose the appropriate adhesive based on the application. Use removable adhesives for short-term promotions. Use permanent adhesives for signs that need to be in place for a long time.

Choosing the Right Label Adhesive

Matching Adhesive to Label Holder Type

Choosing the right adhesive starts with considering the label substrate. Not all adhesives work with all substrates. Some substrates are plastic, others are metal or acrylic. Each material requires a specific adhesive. People want labels that adhere securely, look good, and are easy to remove.

The table below helps in choosing the right adhesive based on the substrate:

| Criteria | Description |

|---|---|

| Material Type | Choose paper or synthetic material labels based on strength or aesthetics. |

| Durability Requirements | Consider water resistance, abrasion resistance, or harsh environments. Choose a strong adhesive to withstand challenging conditions. |

| Application Surface & Environment | Ensure the adhesive is suitable for the surface and can withstand high temperatures, low temperatures, or humid environments. |

Consider the following questions:

- Is the carrier surface smooth or rough?

- Will the label be exposed to water, high temperatures, or low temperatures?

- Does the label need to be attached for a long time or only for a few days?

Permanent adhesives are best suited for securing stationary plastic or acrylic label holders. Removable adhesives are suitable for label holders that require frequent label changes. Repositionable adhesives are ideal for situations where labels need to be moved frequently. For curved or uneven label holders, a specialized adhesive may be more effective.

Tip: Test the adhesive on the actual label holder first. This helps avoid adhesive residue or wasted labels.

Tips for Retail and POS Applications

Busy stores require labels that are quick to apply and durable. In high-traffic areas, labels are frequently touched and moved. The right adhesive can keep shelves tidy and save time.

Here’s a simple step-by-step guide for stores:

- Determine whether you need a permanent or removable adhesive. Permanent adhesives are for fixed signage. Removable adhesives are for promotions or price changes.

- Check the surface. Smooth plastic or glass surfaces work with most adhesives. Rough or damp surfaces require stronger adhesives.

- Consider the temperature. Cold or hot environments require adhesives that can withstand significant temperature variations.

- Test the adhesive in a small area. See if it adheres securely and is easy to remove.

- Consider the label’s application time. For labels that need to stay in place for months, use a permanent adhesive. For labels that need frequent changes, use a removable or repositionable type.

Stores should check these three points during testing:

- Initial tack: Does the label adhere quickly to the surface?

- Adhesion strength: Does it stay adhered after pressure is applied?

- Shear strength: Does it slide or move afterward?

Note: In busy stores, good quality, strength, and ease of use are crucial. A good adhesive saves time and keeps shelves tidy.

Always choose the right adhesive for the application. Permanent adhesives are used for safety labels and product information. Removable adhesives are used for short-term promotional activities. Repositionable adhesives are suitable for situations where staff need to move labels until the correct position is found.

Choosing the right adhesive means fewer problems and neater shelves. Stores that test and make informed choices can keep labels tidy and customers happy.

In a store, choosing the right adhesive for labels is crucial. Permanent, removable, and repositionable adhesives each have their uses. Surface and environmental factors need to be considered. The material of the label holder should also be checked before choosing an adhesive. Communicating with suppliers helps achieve better results. Suppliers can provide advice on how to use adhesives. They can help you choose adhesives suitable for different surfaces. Suppliers can also help stores troubleshoot problems. Testing adhesives beforehand helps stores avoid mistakes. It can keep displays neat and attractive.

FAQ

Which adhesive is best for plastic label holders?

Acrylic adhesives are best suited for plastic label holders. They provide a strong and durable bond. Store employees use them because they are resistant to both cold and heat, and perform well even in humid environments.

Can the labels be removed without leaving sticky residue?

Yes! Removable and repositionable adhesives allow employees to easily remove labels. These adhesives keep shelves and label holders clean without leaving any sticky residue.

How can I test if the adhesive strength is sufficient?

You can apply a sample label to the label holder and press it down for a few minutes. If the label does not slide, the adhesive strength is sufficient.

Are label adhesives safe for food displays?

Most label adhesives used in stores are safe for food displays. Be sure to ask your supplier about food-safe products. Choose adhesives with low odor and no harmful chemicals.